Built for Service

Last year I was gifted an item that once belonged to my grandfather, Otto, rescued by my brother-in-law, Brooks, during an earlier house clean out. It’s an old furniture piece that I had no idea existed until I was made the caretaker. Unexpected acquisitions like this are truly gifts to be savored. They bring instant joy along with a new responsibility, gladly accepted, for custody of an heirloom. I am talking about a machinist’s chest from the “Built for Service” tool chest series manufactured by the Pilliod Lumber Company of Swanton, Ohio.

Machinist chest of old

I don’t recall ever seeing this early twentieth century chest around my grandfather’s workshop and so I have nothing to add regarding provenance. What’s certain is that the chest (cabinet?) contains six small drawers behind a locking front panel. The contents: some metal lathe cutters, drill bits and hand taps, suggest that it once supported the work of a machinist - a precision metalworker. It contained some nice old measuring tools as well, but the value to me was in the container. Fashioned from quarter sawn white oak, stained dark, with a leather handle and stately brass hardware, this 17 x 10 x 8 in. chest had it all.

Six drawers nestled behind lock and key (note label on bottom drawer)

Loaded with tools and bits.

This was a refurbishing (i.e., not a refinishing) Project. By cleaning it up and replacing the missing parts, my primary goal was to make the chest useful again. I had no desire to botox the evidence of wear earned over a lifetime of service. A second goal was to create a tool box for my clockmaking paraphernalia.

History

Most of what I know about this piece comes from an informative blog post (they’re out there!) by a Canadian designer named “Mister G”. His blog, Progress is fine, but it’s gone on for too long, is an entertaining historical commentary on items that he refers to as “old forgotten mechanical crap, things with wheels and/or wings”. If you like any of that stuff you’ll find it worth a look.

According to Mr. G, The Pilliod Lumber Company was founded by T. J. Pilliod in 1896, and they manufactured a variety of small chests for the home and workplace. As with any enterprise, a history of The Pilliod Lumber Co., found in the blog post, records the adaptations necessary for survival amidst the ever shifting selection pressures associated with new technology and market demand (read: acquisitions and restructurings). The final remnant of Pilliod’s business succumbed earlier this century and that final fact makes this refurbishing effort even more meaningful, to me.

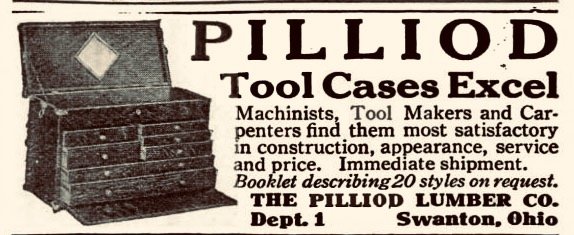

Popular Mechanics advertisement, March 1924

from: Mister G. (2013, March 6). “Vanished Makes: Pilliod Cabinet Company, Swanson, Ohio” [Blog post]. Progress is fine, but it’s gone on for too long.

Refurbishment

All refurbishing begins with a dust cloth and vacuum cleaner, though these are seldom listed in the credits. That initial sweep was followed by a wash with Murphy’s Oil Soap in warm water, a rub down with mineral spirits to remove decades of oily grime, and then a second Murphy’s treatment which sufficiently cleaned the surfaces. There is a line between unwanted dirt and valued patina, and care was taken not to cross into the patina zone.

In addition to dirt there were those usual white spots. Anyone who has refinished furniture knows what I’m referring to. It’s hard to fathom, but the conversation must have gone something like this:

“Honey?! I think I’ll paint the ceiling today.”

“That’s nice, Dear. Don’t forget to spread out all our furniture to catch the drips. Need help with the piano?”

Am I right??? (I added the piano part.) Anyway, those dots of lead were not easily scratched-off the chest and so I decided they could stay. Sheesh!

Collateral damage

Unfortunately, the filthy felt drawer liners were beyond hope and needed to be replaced. Their removal was accomplished by the two step process of: skinning what could be pulled away by hand; followed by a shave using that one shop chisel applied to everything except woodworking. I resorted to mechanical methods because the crystalized glue securing the felt appeared to be the same hide glue used for drawer construction and I did not want to loosen any parts by soaking those drawers in water. Curiously, one drawer had already been re-lined with contact paper. Wouldn’t you love to know the story there? “These five, oil-soaked and smelly felts can stay, but THAT one has to go!”

Shaving Pilliod’s pelts

The drawers were re-lined using today’s 100% polyester felt, and I took it easy on the glue. Next, all wood surfaces were perked-up with an application of Howard’s Feed-N-Wax. I was able to rejuvenate the dry leather handle a bit, too, using prosoft® baseball glove conditioner. Things were beginning to brighten.

Green New Deal

The final step involved the drawer knobs. As evident from that earlier picture, 3 of the original 9 knobs had pulled loose and were missing, one being replaced by a Phillip’s screw implant. In vain, I searched the Web for duplicates. What I found were some small brass knobs from Timesavers, an online clock parts store, that would serve as suitable substitutes. The remaining originals were cleaned-up with mineral spirits, waxed and re-mounted.

All parts in place

Drawers re-loaded

Back in Service

Thanks for reading. And thank you Mister G. for the service you do to humanity by keeping history alive and accessible.